In all aspects of life, whether it is industrial production or home finishing, bundling and fixing are common needs. However, traditional rope or wire tying methods tend to be time-consuming and labor-intensive and not aesthetically pleasing. At this point, an efficient and practical self-locking cable tie will become the ideal assistant to solve the problem.

From the Details: How Self-Locking Nylon Tie Can Change Your Daily Life

Imagine this scenario: you are repairing wires on a bookshelf at home, or a factory needs to arrange a large number of pipe lines in order. Without the right tools to help complete this work, it may take a lot of time and not achieve satisfactory results. Our cable ties made of self-locking nylon tap laminate have completely overturned this situation with their simplicity and ease of use.

You only need to gently pull the tail to achieve quick locking; and thanks to the special tooth design, the tighter the pull, the looseness can be prevented. Therefore, whether it is operating in a small space or facing a complex and changeable working environment, it can handle the challenges easily.

In-depth analysis: the secret behind unique anti-slip and gradual tightening technology

The excellent performance of this product comes from two key technologies- non-standard dog-like structure and continuous pressure mechanism within the adjustable length range :

- -The former automatically forms a barrier to prevent the retreat direction from moving after each insertion action by optimizing the internal gear shape, thus ensuring stability.

- -The latter is to set the spacing relationship between each link with the help of the best proportion parameters obtained by scientific calculation, so that the overall process is smooth and smooth without a sense of jamming.

It is precisely because of the existence of these two innovative processes that have created the safe and convenient wire harness equipment that is popular on the market today.

Scene experience: all-round performance evaluation from industrial to home finishing

next, we will look at its specific performance in different types of application scenarios as follows: first, the construction site: a large number of heavy equipment connection pipeline laying tasks are often involved here. if ordinary metal fittings are selected, problems such as corrosion and damage will easily occur and affect the length of normal operation cycle. However, the new plastic version not only solves the above concerns but also reduces the maintenance cost.

then the maintenance of household electrical appliances: for example, in the process of cleaning the heat sink on the back of the refrigerator, products with specially customized sizes and specifications need to be isolated and protected to prevent secondary damage caused by accidental touch, etc.

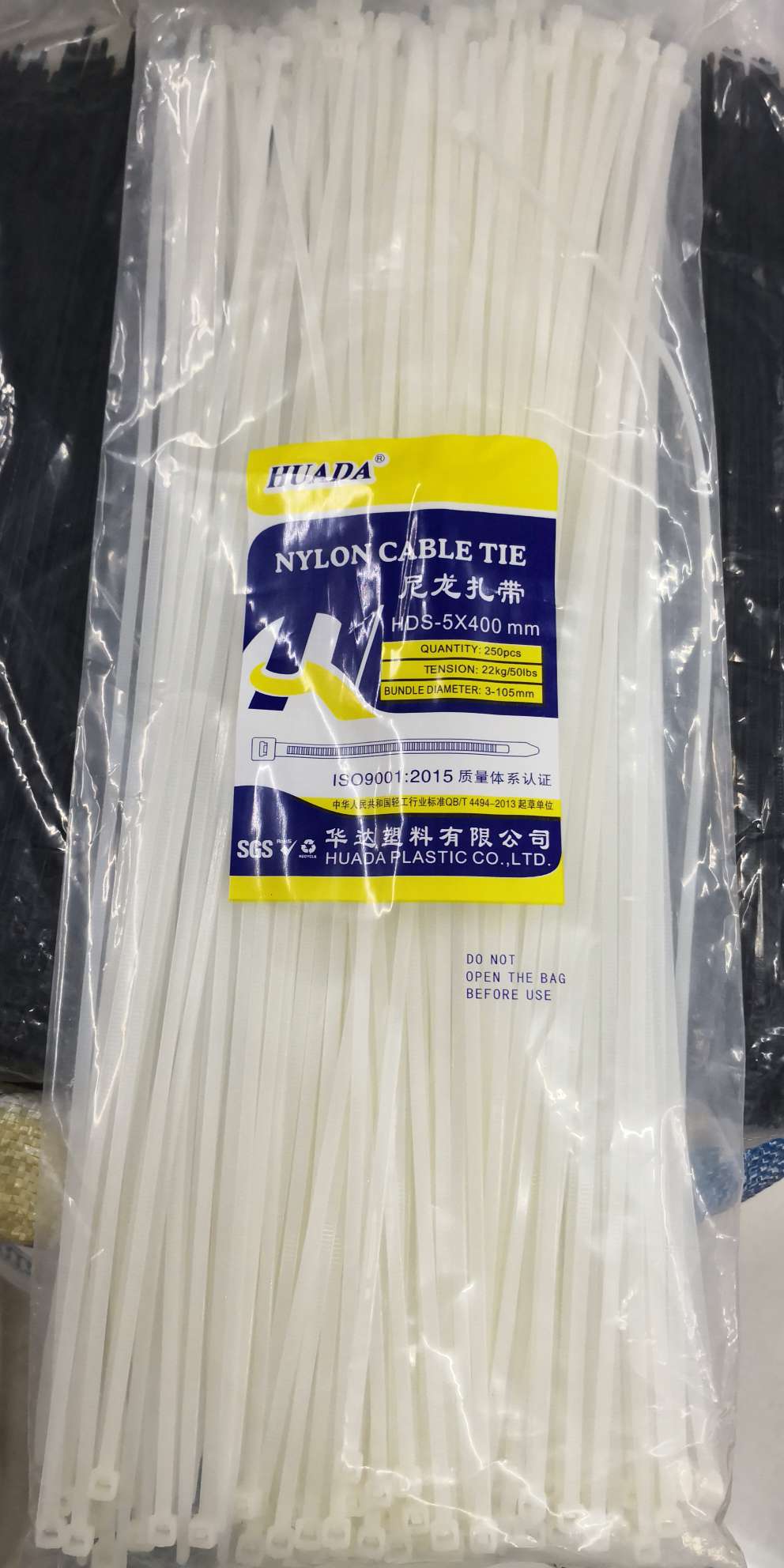

Quality Optimization: Why Choose Our 3 × 60 Strap

In addition to the outstanding advantages of functionality, we have always maintained a high degree of attention to product quality itself. each is made of high-quality polyamide raw materials pressed at high temperature . it has super weather resistance and anti-ultraviolet radiation ability. even if it is exposed to outdoor for a long time, it will not easily deform and break.

it is also worth mentioning that the packaging form is also very humanized: "one thousand pieces" (I .e. each independent box contains a whole thousand pieces of single items) plus the external and three hundred components are combined into a super-large-scale batch shipping scheme, which allows customers to freely choose and order quantities to meet the constraints of different scale procurement budgets and still enjoy the most favorable price discount treatment!

User Voice: Real Case Sharing and Application Suggestions

Feedback from many purchased users indicates that they are very satisfied with the series. "Before, I always thought there was nothing special about this kind of things. Just buy a few and make do with it," said an old engineer who has been engaged in automobile manufacturing for many years. "It was not until I really came into contact with this improved version launched by your company that I found out that there was such a professional and meticulous design concept contained in it!" He also stressed that it is especially suitable for those who often need to disassemble and reassemble, and frequently change the position of parts. The use efficiency is extremely high and the risk of almost zero error rate is very high.

at the same time, a small number of people have put forward several suggestions for improvement, such as whether more color options can be added to distinguish the identification classification management more intuitive and convenient identification and other reasonable demands have been recorded and filed in the future version iteration update plan to be considered and implemented in place.